As urethane casting for low-volume medical device production continues on an upward trajectory, ARRK North America, Inc. is the best option to fulfill your projects. With our rapid prototyping services worldwide, count on the fastest turnaround and cost-effective urethane casting for low volume manufacturing with extraordinary attention to detail, delivering prototypes that look and feel like the end product.

The medical device industry is spearheading the design and manufacturing sector of a wide range of products. These products include everything from devices to diagnose and treat illnesses to devices that improve overall health in patients. The top players in the medical device industry bring in billions of dollars in revenue year after year.

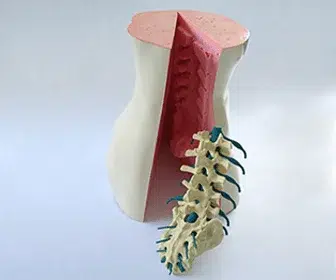

ARRK’S SPECIALIZED SERVICE OFFERS FULL PRODUCTION-QUALITY PARTS FOR THE MEDICAL SECTOR.

Depending on the process used, urethane casting allows for a more limited investment in tooling and materials while providing quick access to markets, rapid response to shorter product life cycles, and a bridge between initial prototypes and high-volume production.

Some of the ways urethane casting helps the prototyping process for medical devices include:

- Creates a shorter time span between building a few prototypes and a full-scale production

- Reduces total cost

- Provide quick iterations according to market needs

- Respond quickly to shorter product life cycles

- Lower financial risks

MEDICAL DEVICES: IT’S ALL IN THE DETAILS

Because medical devices are essential tools for healthcare and directly impact public health and quality of life, their safety is imperative. To create desirable outcomes for all parties and prevent device recalls, companies must follow relevant medical device manufacturing standards.

These quality standards help ensure that a manufacturing or design process can consistently produce the quality required to serve patients and healthcare professionals.

ARRK is part of an important step to help build innovative medical devices and continue caring for the end-user of your customers.

USING URETHANE CASTING IN THE MEDICAL INDUSTRY

Using urethane casting is the best option when prototyping a new medical technology or invention. Providing urethane casting parts for end-use for the medical industry goes from rigid, flexible, or just what it needs, and it is part of ARRK’s capability.

Besides the material, the creation time is reduced significantly compared with other manufacturing services. Using urethane casting is the closest prototype service someone can provide with a working prototype.

COLLABORATING WITH AN EXPERIENCED MANUFACTURING TEAM IS KEY

Having a team of design engineers, production managers, and excellent craftsmanship gives an excellent product development result. Our team handles fields such as the aerospace & defense industry, consumer goods, automobile, and other manufacturing industries.

Contact us at (800) 735-2775 or fill out our form to Get a Quote.