It is not enough to work on the design of exterior automotive components for a better look. It’s crucial to ensure all internal car parts are also taken care of with the utmost attention to detail for better performance. Taking this into account, having a high-quality automobile provided to the market, makes your company have a favorable option to consumers, and we believe implementing CNC machining for your automotive components can make the difference.

How to improve quality in automotive components

Using CNC machining for creating prototypes has been shown to simplify complex work. Specifically, the automotive industry has seen improvement in both prototyping and production applications by:

- Producing high-quality parts

- Creating functional prototypes

- Wider available materials

The wide range of available materials compatible with CNC machining makes the production of a final part even quicker than traditional manufacturing. However, it is even harder in traditional manufacturing to keep reaching all critical dimensional points in every part produced.

Creating functional prototypes and producing high-quality parts don’t come only from having the technology. Having faster and newer equipment in manufacturing does help, even having the software tools for designing, but everything comes down to the expertise of the one behind them.

Using a suitable team for the job

Dedicated teams such as those in ARRK North America can help your project efficiency and reach project goals. An experienced team best handles the actual complex projects with efficiency.

- We can work with 3 axis CNC machining, which can remove material on the three primary directions corresponding to a flat surface axis: X, Y, and Z.

- We can also work with 5 axis CNC machining, machining removing material in five directions: X, Y, Z, and two additional axes in which the tool rotates.

Besides using a suitable machine for the better axis, we can provide general master model tolerances, but we can guarantee higher tolerances with prior agreement.

| Machining master models | ± .005 in. or ±.13mm Standard or supplied drawing tolerances • Example: .X ± .030 .XX ± .010 .XXX ± .005 |

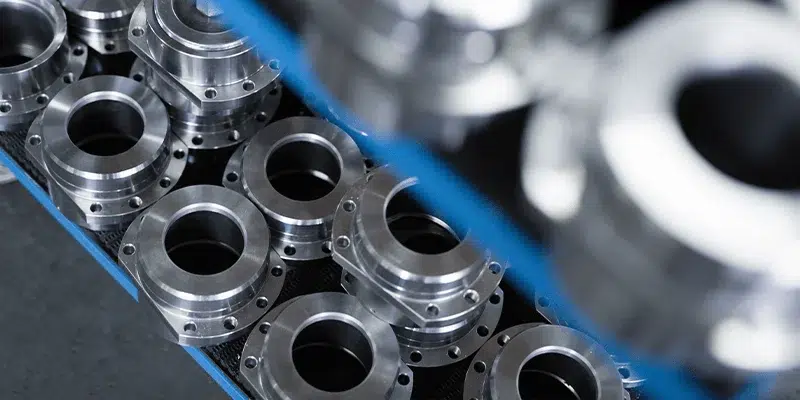

CNC machining can create parts such as:

| • Dashboard frame • Combustion chambers • Gas gauge • Constant velocity joint | • Carburetor housings • Valve retainers • Bushings |

CNC machining can be used to create several important components of:

| • Combustion engine • Lighting • Suspension components | • Exhaust parts • Fluid system components • Drive axles components |

ELIMINATE HANDING OFF AND REWORKING ON YOUR PRODUCTION

Low-volume CNC machining enables a high-precision production to be met with high accuracy. The CNC production process combined with a team that takes advantage of the manufacturing process provides the desired shape with the needed measurements.

Thanks to the benefits, it creates a favorable chain reaction of accomplishing shorter lead times and helping increment company earnings. In addition, we know that working with ARRK North America will improve the production of your automotive components.

The most important thing that all manufacturers should have: is precision & experience for execution, and we can provide it.

Get in contact with an ARRK representative for more information.